Part II of this series explored how the bridge route would need to widened to fit my bridge. I do not have the skills or tools to make this happen, but luckily I work with someone who does!

Measure once and cut twice. No wait that’s backwards.

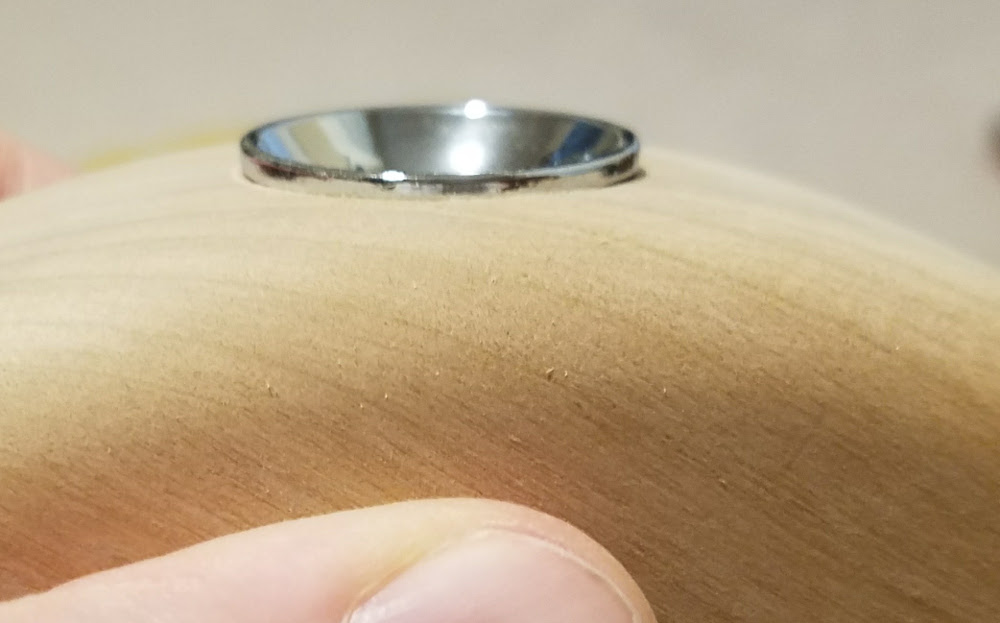

Now the guitar is ready to finish!